Our Services

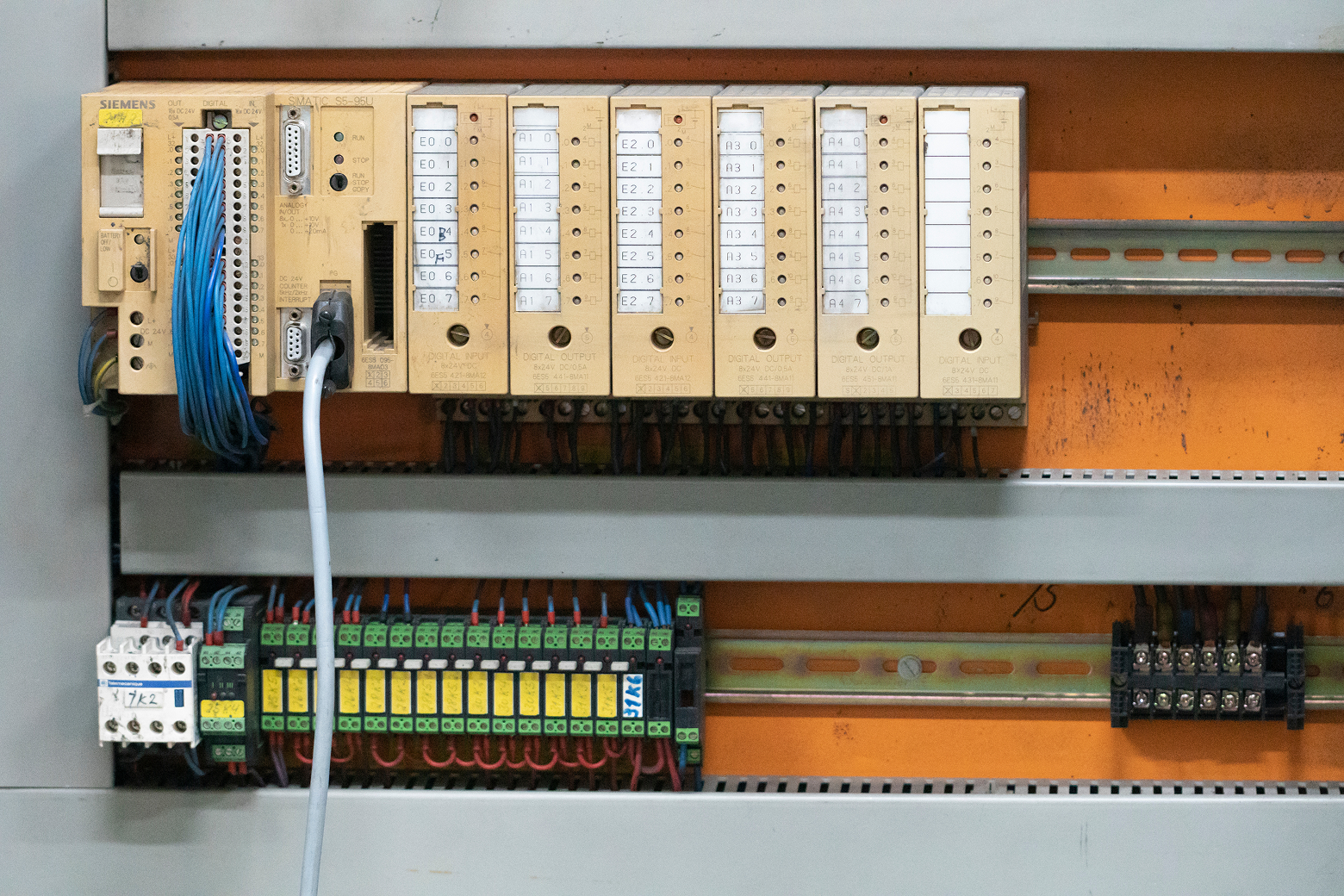

Emergency Troubleshooting

We offer 24/7 rapid fault diagnosis and isolation for PLC and HMI issues, network and communication problems, drive and motion control faults, and safety system diagnostics. Call us when a production line stops unexpectedly, intermittent alarms occur, communication errors arise, or equipment behaves erratically. Our team responds immediately with a systematic troubleshooting approach, delivers clear documentation of findings, and provides prioritized repair recommendations to restore operations quickly and reliably.

Control System Integration

Typical projects include adding new equipment to existing production lines, replacing obsolete controllers, connecting previously isolated systems, and modernizing overall control architecture. We deliver complete solutions through new system design and implementation, seamless migration from legacy platforms, multi‑platform integration, and custom SCADA development. Our expertise in industrial networking—such as Ethernet/IP, Profinet, and Modbus—ensures reliable communication and a scalable, future‑ready control system.

Preventative Maintenance

We provide proactive maintenance and lifecycle support through regular system health checks, verified and up‑to‑date backups, scheduled battery replacements, and disciplined software version management. Our services also include keeping documentation current and reviewing schematics to ensure accuracy. This proactive approach reduces unexpected downtime, extends equipment lifespan, improves overall system reliability, and enables better planning for future upgrades and expansions.

Equipment Upgrades

We specialize in equipment retrofits and control system upgrades designed to minimize downtime and keep operations running smoothly during changeovers. Our approach emphasizes careful planning and implementation to reduce production interruptions, thorough verification to ensure upgrades integrate seamlessly with existing equipment, and clear documentation of current systems to support long‑term maintainability. Our capabilities include PLC and HMI upgrades to the latest generations, safety system enhancements, drive and motor control updates, and network infrastructure improvements. These services address common challenges such as obsolete or unsupported parts, the need for added functionality, evolving compliance requirements, and demands for improved performance and reliability.

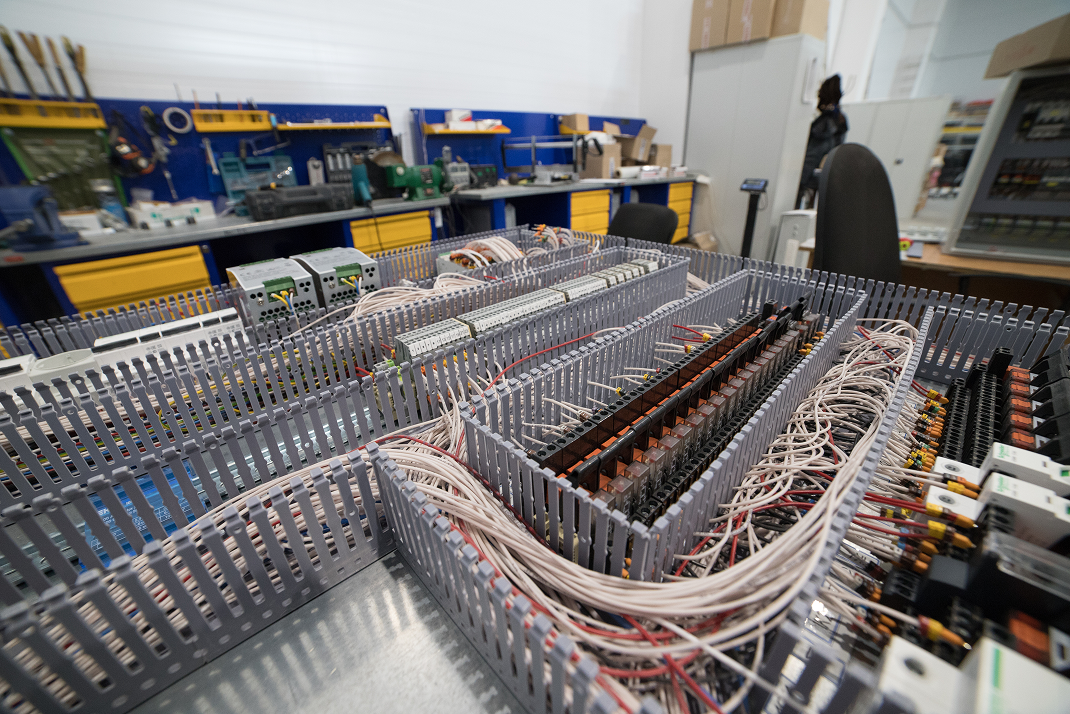

New Panel Design and Fabrication

We design and build custom control panels tailored to your application, providing complete electrical schematics in AutoCAD, detailed wire labeling, and thorough documentation to support long‑term maintenance. Our design and fabrication process is aligned with UL508A, UL698A, NFPA 79, NEC compliance, and customer‑specific standards. Each panel is fully tested through factory acceptance testing to verify functionality and quality before delivery, ensuring a reliable, well‑documented solution that integrates smoothly into your operation.

Schedule your appointment with ease and confidence. Our team of engineering and technology experts are ready to provide the solutions you need, tailored to your specific requirements.

Contact us

Interested in working together? Fill out some info and we will be in touch shortly. We can’t wait to hear from you!